open-die forgings

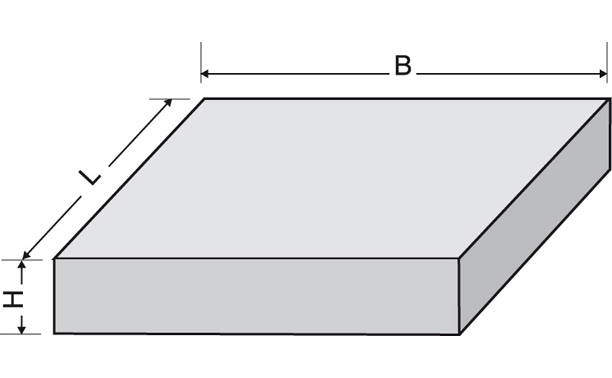

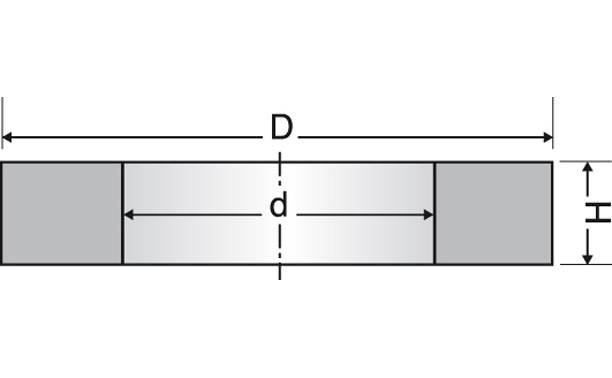

RECTANGULAR BARS AND PLATES

| Length | max. | 4000 mm |

| Width | max. | 1300 mm |

| Height | max. | 400 mm |

| Weight | max. | 5 to |

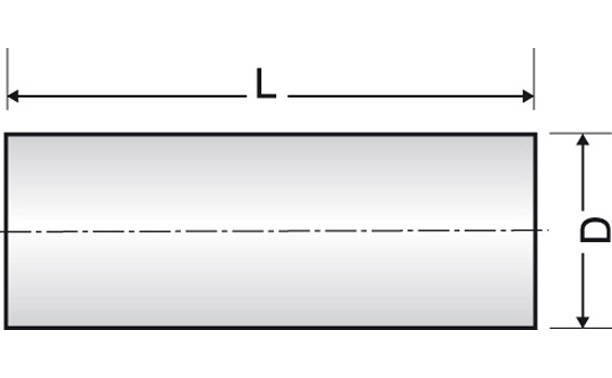

Shafts

| Length | max. | 4000 mm |

| ∅ | max. | 500 mm |

| Weight | max. | 5 to |

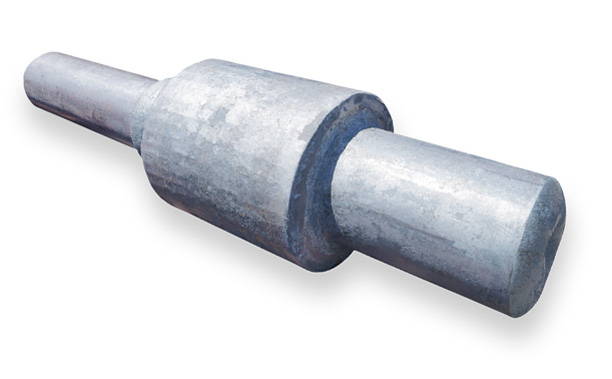

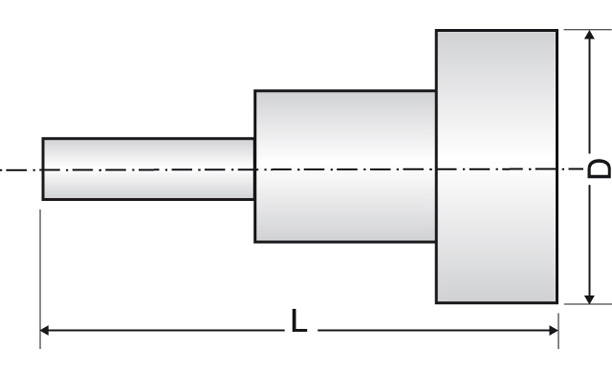

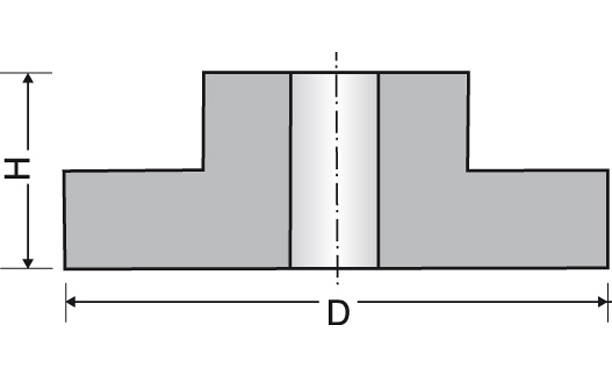

shafts, flanged shafts, rotors etc.

| Length | max. | 4000 mm |

| ∅ | max. | 1000 mm |

| Weight | max. | 3 to |

rounds blanks, hubs , solid or punched hole

| Height | max. | 400 mm |

| ∅ | max. | 1500 mm |

| Weight | max. | 5 to |

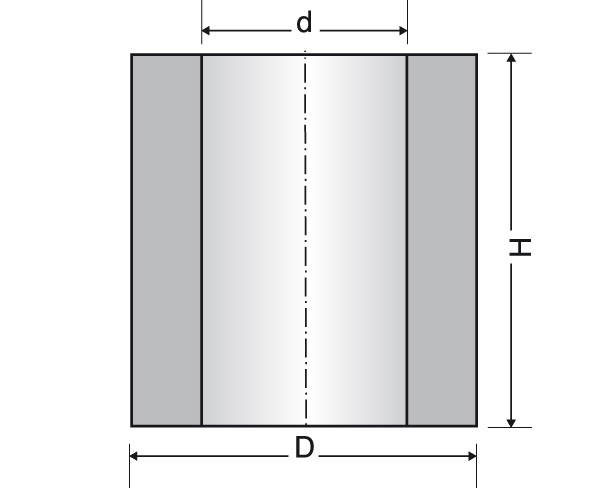

sleeves

| ∅ Outside | max. | 1300 mm |

| ∅ Inside | min. | 200 mm |

| Height | max. | 900 mm |

| Weight | max. | 5 to |

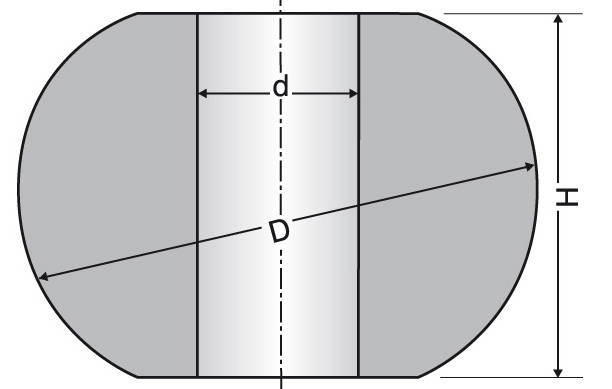

seamless hot rolled forgings

ringS in recTANGULAR SHAPE

| ∅ Outside | max. | 3700 mm |

| ∅ Inside | min. | acc. to requ. |

| Height | max. | 700 mm |

| Weight | max. | 5 to |

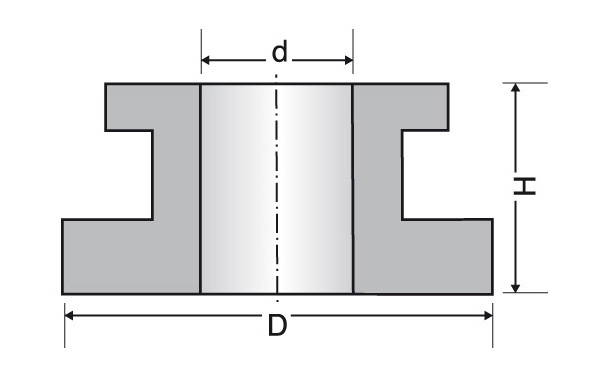

profiled rings

| ∅ Outside | max. | 3000 mm |

| ∅ Inside | min. | acc. to requ. |

| Height | max. | 600 mm |

| Weight | max. | 5 to |

balls

| ∅ Outside | max. | 920 mm |

| ∅ Inside | min. | acc. to requ. |

| Height | max. | 700 mm |

| Weight | max. | 1.7 to |

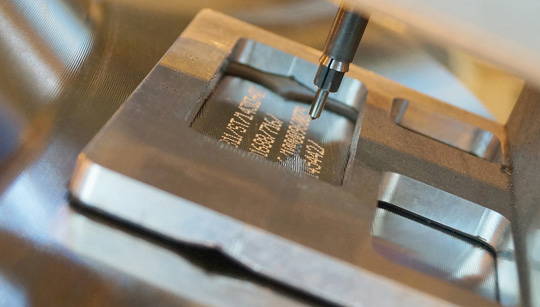

Safety and long product life

Forged parts from STOOSS are outstanding because of their:

material selected on the strength of its analysis and degree of purity

exact shaping

ideal degree of forming

optimum grain structure

minimum allowances, narrow tolerances

thermal treatment relevant to the application

Moreover, they offer exceptional advantages:

excellent manufacture in respect of surface quality and accuracy of form

suitable for processing on CNC

machines

reduction of mechanical processing time, thus saving costs

high degree of security against fatigue cracks